The transition to an electric powertrain for two- and three-wheelers has yet to be implemented extensively. It is slightly more complicated than simply swapping out the combustion engine to glue in an electric motor.

Electric Motors in E2Ws and E3Ws

Compared with conventional vehicles, electric vehicles have great advantages:

-

- high efficiency of energy conversion,

- low noise,

- zero emission,

- simpler structure and easier maintenance: the load-carrying properties and wide range of speed control characteristics of electric motors allow the removal of mechanical devices such as clutch and gearbox.

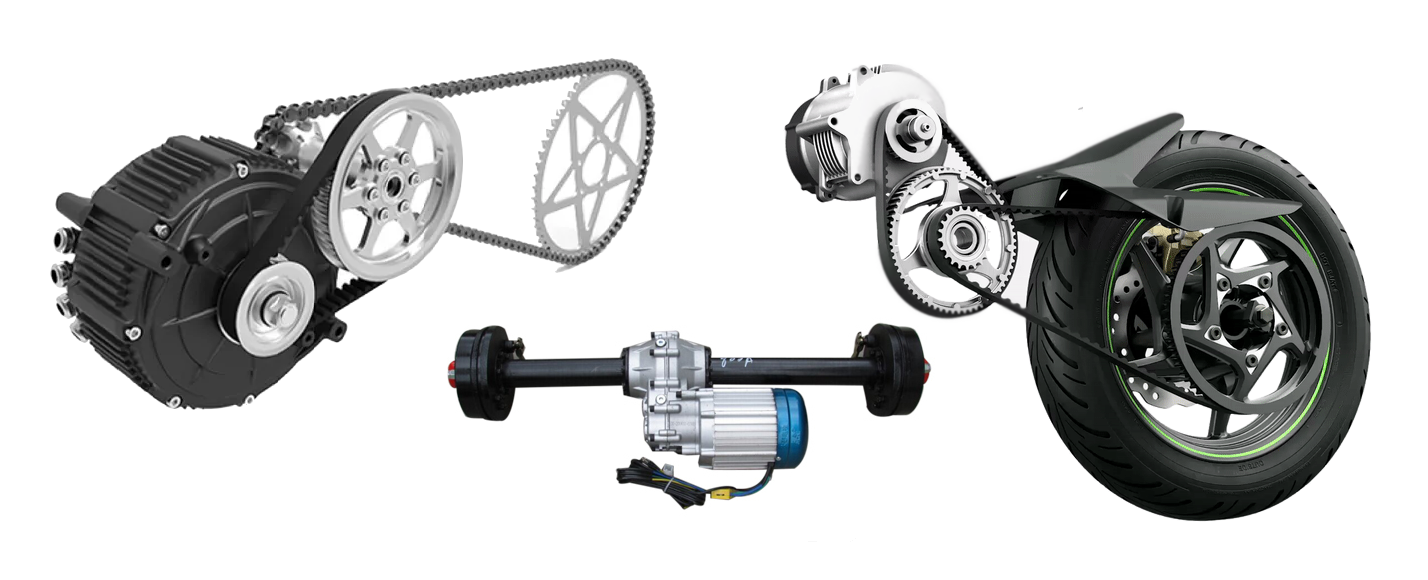

On the other hand, the design of vehicles has been optimised, for over a hundred years, for the use of internal combustion engines. Especially for electric two- and three-wheelers, the transition to electric drive has not changed the design and too often the electric motors are simply positioned in the area where combustion engines were located, whereas power and torque are brought to the wheels by means of a mechanical transmission.

The result is not only an increased and unnecessary complexity, but also higher mechanical losses and higher costs, often justified by several different means. Nevertheless, it is worth considering that the “one size fits all” or the “it has always done like this” approaches are wrong and especially for E2W and E3W it is possible to choose a different and better design approach.

Electric Hub Motors

In-Wheel hub motors are the most advanced electric vehicle driving technology. Two, three or more motors are installed directly in the wheels and action them into motion directly. There are commonly known as electric wheel motors, a solution especially suitable for pure (not hybrid) electric vehicles. Hub motors are available in all sizes and power, with integrated or separate rim and for any type of vehicle.

The wheel hub motor drive completely abolishes the power train components. It integrates the motor, suspension system and brake system in the rim, achieving compact vehicle structure, lower center of gravity and improved driving stability at the cost of an higher unsprung mass. However, for E2W and E3W the latter penalty is negligible.

Further advantages come from the possibility of implementing torque vectoring (with suitable control electronics) and full wheels drive, something that has never been really possible before on two wheelers.

Electric vehicles that adopt wheel hub motor drive mode offer compact structure, high utilisation ratio of the vehicle’s interior space, lower center of gravity, good driving stability, easy intelligent control and many other unique advantages such as reliability, lower maintenance cost, better safety, torque management and other aspects compared with other drive schemes.